STINGER

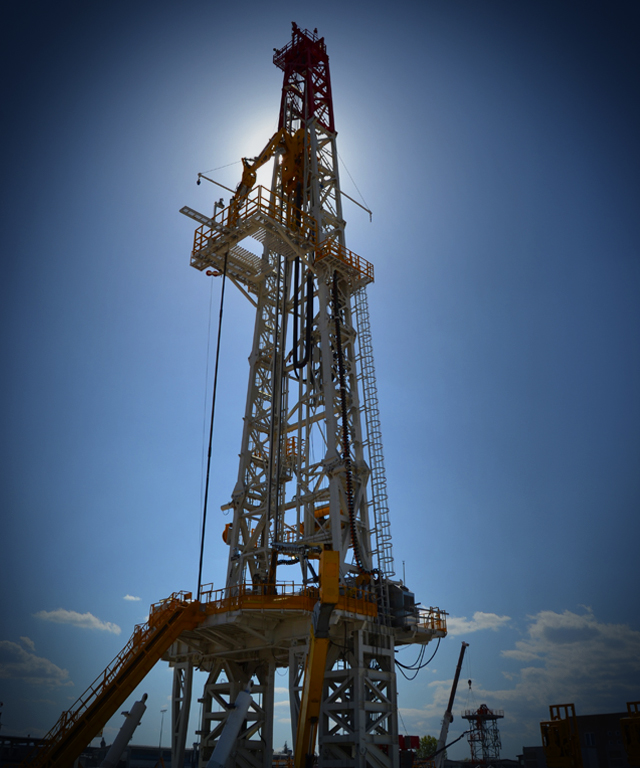

Over twenty years ago we designed the first unmanned semiautomatic and then fully automated pipe handling systems for onshore drilling applications. Since then, numerous solutions for horizontal pipe handling, small footprint vertical handling and the flexible THV (Tubulars Horizontal to Vertical) have been implemented in the over 500 Drillmec drilling rigs around the world today.

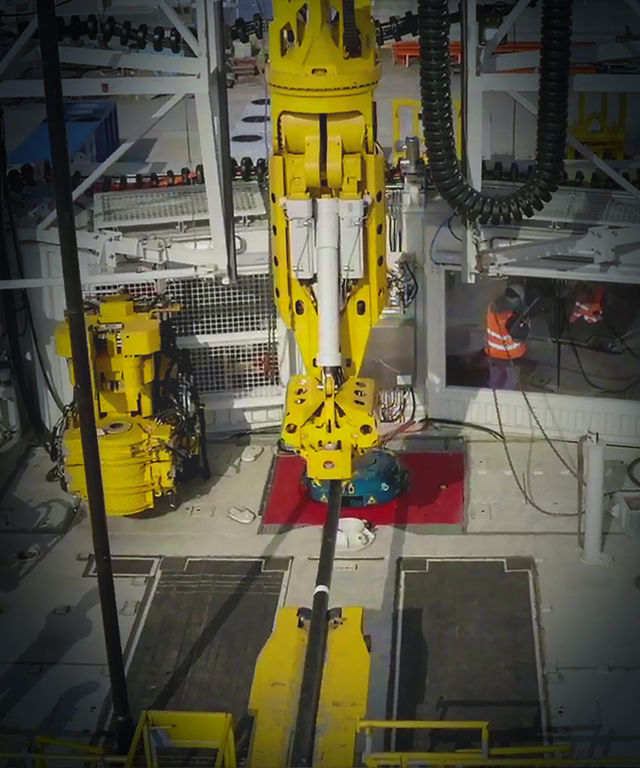

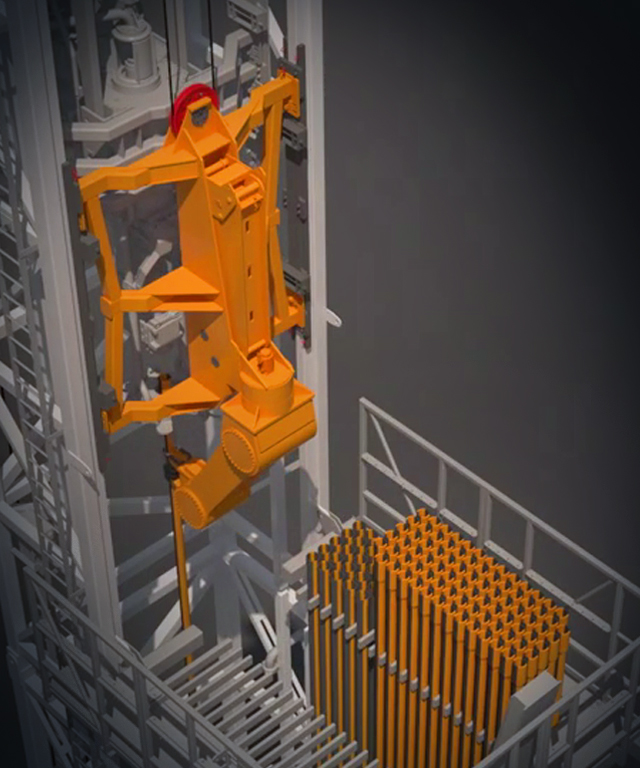

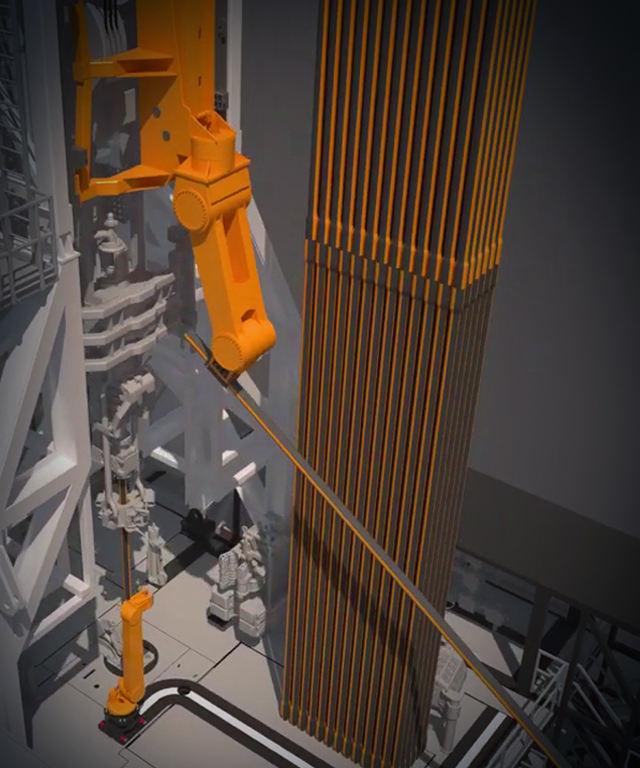

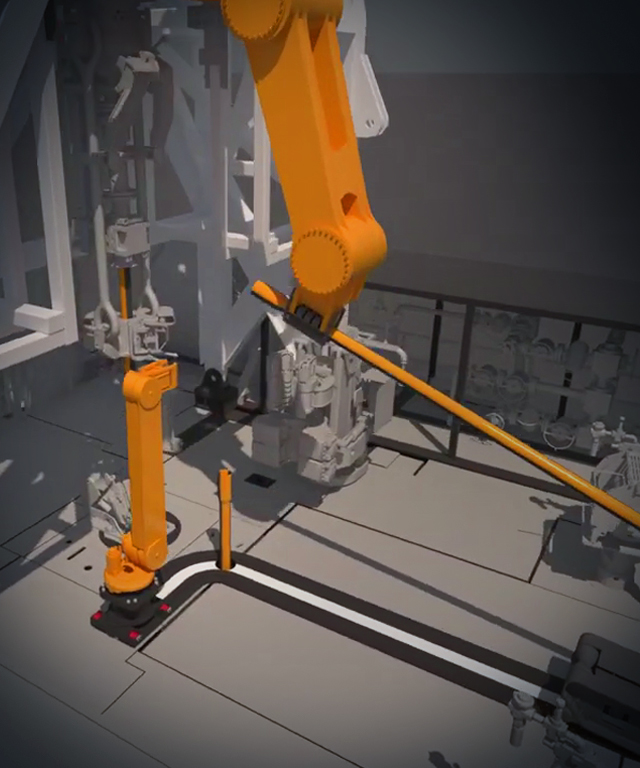

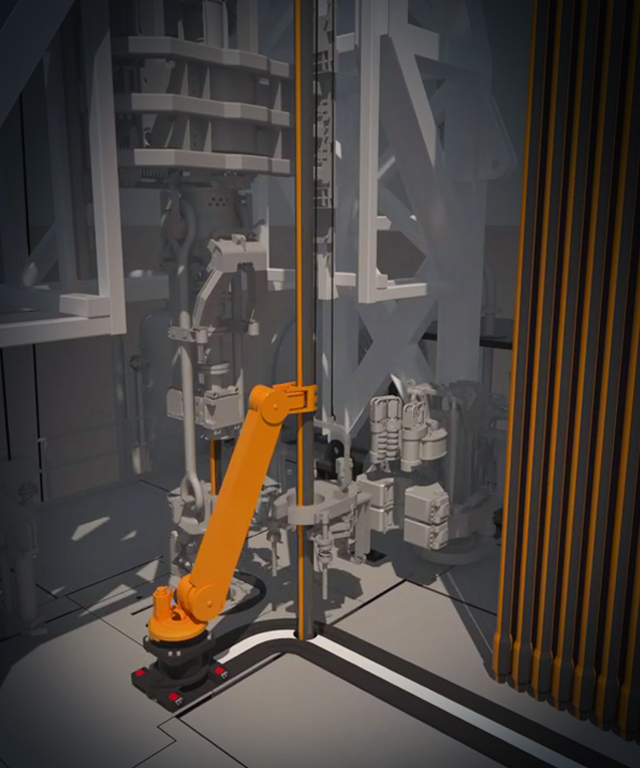

Stinger is the next step, where industrial robotics meets experience and excellence in innovation and engineering. Our new pipe handling system allows to build up and rack back stands of drill pipe, drill collars and casing offline, while drilling.

The theoretical comparison with the conventional approach of handling pipes emphasizes how offline stand building leads to 20% efficiency gains on tripping time and zeroes accidents on the drill floor. All tubular handling occurs through semiautomatic and automatic sequences, enhancing safety and predictability by bringing people out of the line of fire.

TUBULAR RANGE (Offline Stand Build & Rack-Back)

• Drill Pipe : from 2 ⅜” thru 6 ⅝” OD in automatic handling mode

• Drill Collars up to 9” in semiautomatic handling mode

• Casing up to 7” in automatic handling mode

CAPACITIES

• Max Tubular Capacity in automatic catwalk pick up mode: 1320 lbs

• Max Tubular Capacity in semiautomatic catwalk pick up mode: 22000 lbs

• Max Tubular Capacity in automatic mode: 2800 lbs

KEY FEATURES OF OUR STINGER

The Stinger pipe handling system is designed in such a way that it can move the stand from the rack to the well center axis and back, playing a key role in the tripping in/out operations. This operation can be done in automatic and semiautomatic mode.

The Stinger pipe handling system allows for offline stand building of tubulars away from the activities at well center therefore without interfering with drilling operations. The offline stand building cuts the drill string running time and that affects the overall cost of operating the rig.

The Stinger pipe handling system also reduces the need for personnel on the drill floor by directly handling heavy objects keeping the work environment safe and secure.

The Stinger pipe handling system also reduces the need for personnel on the drill floor by directly handling heavy objects keeping the work environment safe and secure.

Specs

| OD | # | Total Weight | Pick Up From Catwalk | Tripping | Gripper Clamp | |

|---|---|---|---|---|---|---|

| inc | lbs/ft | lbs | ||||

| DPs | 2 3/8" | 7.6 | 700 | Automatic | Automatic | GRIPPER 2 + Reduction |

| DPs | 2 7/8" | 11.3 | 1,340 | Automatic | Automatic | GRIPPER 2 + Reduction |

| DPs | 3 1/2" | 15.5 | 1,426 | Automatic | Automatic | GRIPPER 2 |

| DPs | 4" | 14.0 | 1,288 | Automatic | Automatic | GRIPPER 2 |

| DPs | 4 1/4" | 15.4 | 1,416 | Automatic | Automatic | GRIPPER 2 |

| DPs | 4 1/2" | 16.6 | 1,527 | Automatic | Automatic | GRIPPER 1 |

| DPs | 4 1/2" | 20.0 | 1,840 | Automatic | Automatic | GRIPPER 1 |

| DPs | 5" | 19.5 | 1,794 | Automatic | Automatic | GRIPPER 1 |

| DPs | 5" | 25.6 | 2,355 | Automatic | Automatic | GRIPPER 1 |

| DPs | 5 1/2" | 24.7 | 2,272 | Automatic | Automatic | GRIPPER 1 |

| DPs | 6 5/8" | 29.0 | 2,668 | Automatic | Automatic | GRIPPER 1 |

| HWDP | 3 1/2" | 24.4 | 2,244 | Automatic | Automatic | GRIPPER 2 |

| HWDP | 4" | 28.6 | 2,631 | Automatic | Automatic | GRIPPER 2 |

| HWDP | 4 1/2" | 44 | 3,900 | Semiautomatic | Semiautomatic | GRIPPER 1 + Drill Collar Claws |

| HWDP | 5" | 50 | 4,650 | Semiautomatic | Semiautomatic | GRIPPER 1 + Drill Collar Claws |

| HWDP | 5 1/2" | 57 | 5,250 | Semiautomatic | Semiautomatic | GRIPPER 1 + Drill Collar Claws |

| HWDP | 6 5/8" | 74 | 6,720 | Semiautomatic | Semiautomatic | GRIPPER 1 + Drill Collar Claws |

| DC | Up to 9 1/2" | 200.0 | 18,400 | Semiautomatic | Semiautomatic | GRIPPER 1 + Drill Collar |

| CSG | 4 1/2" | 15.0 | 1,380 | Automatic | Automatic | GRIPPER 2 |

| CSG | 5" | 24.1 | 2,217 | Automatic | Automatic | GRIPPER 2 |

| CSG | 5 1/2" | 26.8 | 2,465 | Automatic | Automatic | GRIPPER 1 |

| CSG | 6 5/8" | 24.0 | 2,208 | Automatic | Automatic | GRIPPER 1 |

| CSG | 7" | 23.0 | 2,116 | Automatic | Automatic | GRIPPER 1 |

| CSG | 7" | 26.0 | 2,392 | Automatic | Automatic | GRIPPER 1 |