POWER CATWALKS

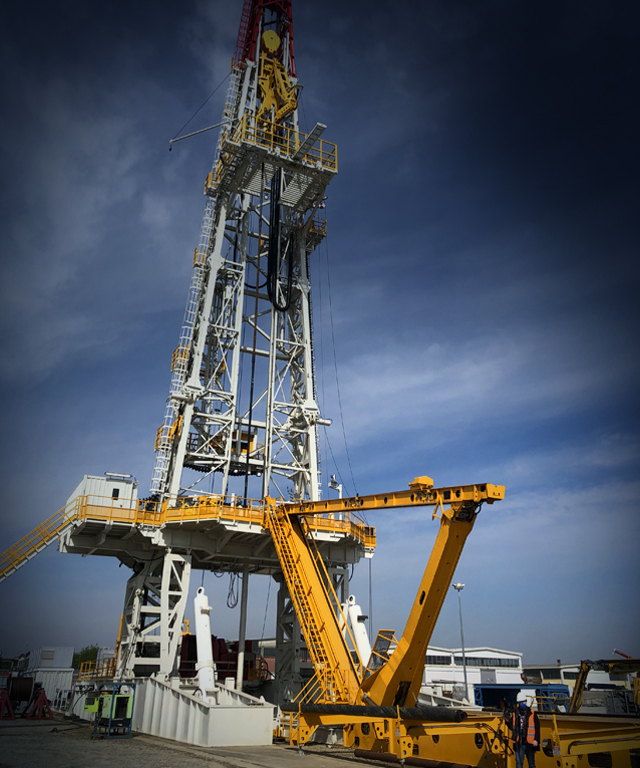

Power catwalks from Drillmec are part of the results of the investment in our rig automation program started in the early ’90s. We design and produce automatic pipe handling systems or power catwalks to work as single mechanization components or a complete hydraulic rig to support drilling processes for better pipe handling safety and efficiency.

We specially design our automated catwalks to allow easy operations and seamless integration with different types of drilling and workover rigs. For improved safety and efficiency, our power catwalks use wireless and remotely controlled panels which allow for remote operation from anywhere around the rig. This feature reduces hazards and risks around the drill floor and conventional pipe handling process thus improving safety on the rig.

MAIN FEATURES OF OUR POWER CATWALKS

• Features a tubular length range of between 25 feet (7.62 m) to 48 feet (14.6 m).

• Lifting capacity range of between 1500 lbs (680 kg) to 22,000 lbs (10,000 kg).

• Drilling floor height range of between 5 feet (1.5 m) to 40 feet (12.19 m).

• Can feature a manual or automatic pipe feeding system.

• Cycle time of 25 to 80 seconds.

• All models feature both local control panel plus wireless remote control.

• Can withstand an extreme temperature range of -40 °C (-40 °F) to 55 °C (132 °F)

FEATURES OF OUR POWER CATWALKS

• Pipe Range: DP/DC/Tubing range 2 or 3

• Pipe Size Range: Up to 2 3/8 to 20 inches (193.6 mm to 508 mm)

• Maximum Tubular Weight Range: 1,500 lbs to 10,000 lbs (680 kg to 4,540 kg)

• Drilling Floor Height Range: 5 feet to 40 feet (1.5 m to 12.9 m)

• Pipe Range: DP/DC/Tubing range 2 or 3

• Pipe Size Range: 2 3/8 inches to 13 3/8 inches (15.9 mm to 339.7 mm)

• Maximum Tubular Weight Range: 6,670 lbs to 7,000 lbs (3,000 kg to 3,200 kg)

• Drilling Floor Height Range: 15.4 feet to 25 feet (4.7 m to 7.62 m)

• Pipe Range: DP/DC/Tubing range 2 or 3

• Pipe Size Range: 2 7/8 to 10 inches (60.3 mm to 254 mm)

• Maximum Tubular Weight Range: Up to 22,200 lbs (10,000 kg)

Specs

| Tubular Lenght Range | Tubular OD Range | Lifting Capacity | Drilling Floor Height Range | Tubular Loading | Cycle Time | Control | Transport Dimensions | Estimated Overall Dry Weight | Temperature Range | Hydraulic Power Unit | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| m ' | mm " | kg lbs | m ' | mm | kg | °C | |||||

| APC-50 | 14,3 up to 47 | 193,6 up to 7 5/8 | 680 1500 | 1,5 to 4 5 to 13,1 | Automatic with pipe feeding system | - | Local control panel and wireless remote control for Safe Area | 12558 x 974 x 1216 | 5.110 | 0 / +55 | Not included |

| APC-100 | 9,53 up to 31 3/8 | 60,3 to 203 2 3/8 to 8 | 3000 6600 | 4,7 to 6 15,4 to 19,6 | Auto feeding system with pipe racks, indexers, safety pins and kickers | - | Local control panel and wireless remote control for Safe Area | 10960 x 2260 x 1453 | 7.000 | 0 / +55 | Not included |

| APC-200 | 7,62 up to 14,63 25 up to 48 | 60,3 to 508 2 3/8 to 20 | 4536 10000 | 7,62 to 12,19 25 to 40 | Auto feeding system with pipe racks, indexers, safety pins and kickers | Approximately 25 seconds | Local control panel and wireless remote control for Safe Area | 17700 x 2884 x 2840 | 41.000 | 0 / +55 | Integrated HPU (in the catwalk frame), 90 kW 400V-60Hz |

| APC-300 | 14,6 Range 2 or 3 up to 48 | DP OD from 73 to 168, DC OD up to 254, casing OD up to 914 DP OD from 2 7/8 to 6 5/8, DC OD up to 10, casing OD up to 36 | 10000 up to 22000 | - | Manual | Approximately 45 seconds | Wireless remote control panel suitable for safe area, local hydraulic panel, for emergency operations | 20271 x 2910 x 4170 | 40.000 | -20 / +40 | Not included |

| THV-7700 | Range 3 Single 14,32 up to 47 | 60,3 to 339,7 2 3/8 to 13 3/8 | 3200 7000 | 4,87 to 7,62 16 to 25 | A pivot arm rotates 90° on the side to receive the tubular from the pipe rack | Approximately 80 seconds | Wireless remote control for safe area | 16598 x 2591 x 2864 | - | -20 / +40 | Integrated HPU (in the catwalk frame), 400V-50Hz / 480V-60Hz |