IRON ROUGHNECKS

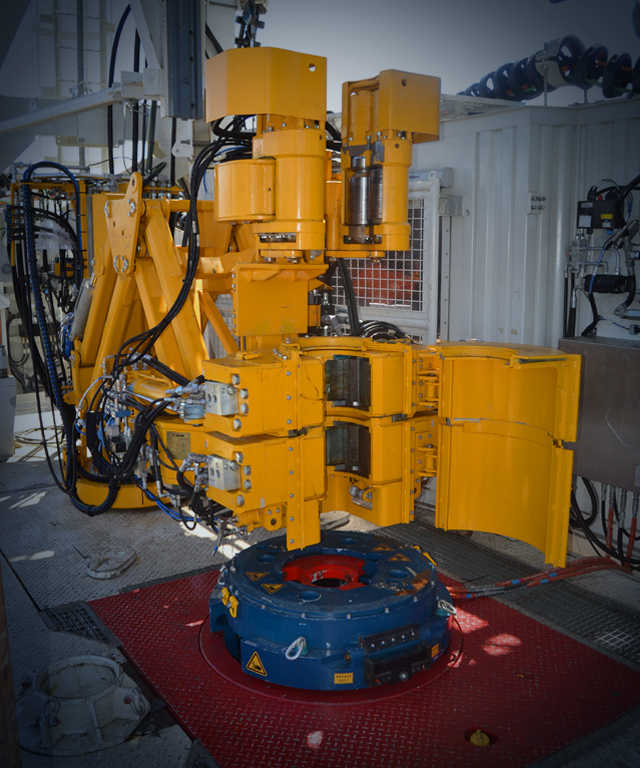

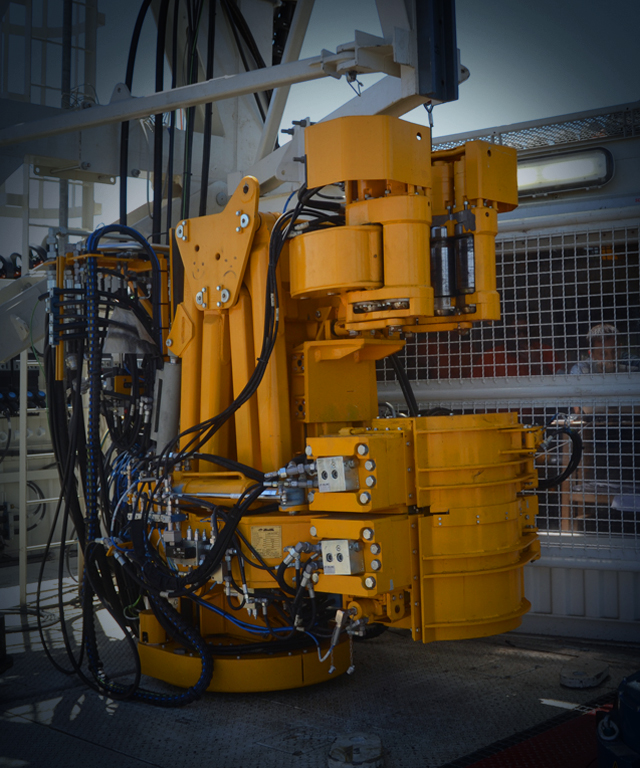

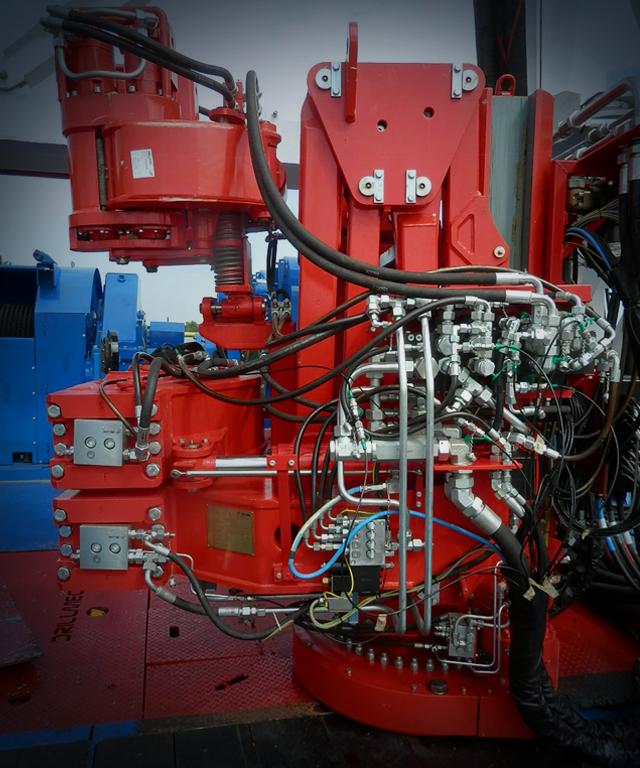

Iron roughnecks are an integral part of drilling operations. It does the major work of connecting and disconnecting tubular with the aid of power tongs or clamps. At Drillmec, we design and manufacture high torque performance iron roughnecks with efficient and quick operations.

Our iron roughnecks comprise rotating clamps, spinning system, pedestal/positioning device, and a set of hydraulic cylinders for vertical and horizontal power tong moving.

Main Benefits of our Iron Roughnecks Design

• Easy installation and handling procedures.

• Dedicated Hydraulic Power Unit and air tank capacity of 600 to 700 litres.

• Equipment can be installed on the drill floor in compliance with Atex Ex II 2G (Zone 1).

• Cooling system comes in two optional air/oil or water/oil systems.

• Features a remote-control panel with several commands, such as make-up break-out, spin/torque selector, emergency stop, vertical moving, horizontal moving, and angle adjustment.

• Features two 17 tons rated pad, mounted at the top for better lifting during transportation.

• Features variable electrical tension/frequency inputs (400-50 / 460-60).

• High torque performance with a wide range of outer diameter availability.

• Features a limit switch that stops upper clamp rotation during makeup phase.

• Controls are on the handling arm frame in the case of emergency.

KEY FEATURES OF OUR IRON ROUGHNECKS DESING

Our iron roughnecks are designed to be installed directly on the rig floor using a pedestal. The power system can either be a stand-alone hydraulic power unit or the rig’s auxiliary hydraulic power unit.

The control panels are in the drill cabin on the drill floor and have a long cable for remote operations from a safe distance.

• Tubular Outer Diameter Range of between 3 ½” to 11” (89 mm to 280 mm).

• Maximum make up torque of 110,000 lbs-ft (15,000 daNm).

• Maximum break out torque of 132,000 lbs-ft (18,000 daNm).

• Spinning speed of 100 rpm (with 5” OD DP).

• Spinning torque of 2950 lbs-ft (400 daNm).

• Horizontal travel of 88.6” (2250 mm).

• Vertical travel of 39.4” (1000 mm).

• Hydraulic requirement of 5000 psi, 42 gpm (345 bar, 160 l/min).

• Weight of 113,700 lbs (6,200 kg).

• Working Conditions of between -20°C and +50°C.

Specs

| Tubular OD Range | Max Make Up Torque | Max Break Out Torque | Spinning Speed | Spinning Torque | Horizontal Travel | Vertical Travel | Hydraulic Requirement | Weight | Working Conditions | |

|---|---|---|---|---|---|---|---|---|---|---|

| mm " | Nm lbs*ft | Nm lbs*ft | rpm | daNm lbs*ft | mm " | mm " | bar - l/min psi - gpm | kg lbs | °C | |

| PCT-130 | 89 to 280 3 1/2 to 11 | 150,000 110,000 | 180,000 132,000 | 100 with 5"OD DP | 400 2950 | 2250 88.6 | 1000 39.4 | 345 bar - 160 l/min 5000 psi - 42 gpm | 6200 113700 | -20 up to +50 |