HH SERIES RIGS

Drillmec’s Hydraulic drilling rigs emerged from the need to meet the demands of today’s E&P companies that require a rig with high performance, lower NPT, lower operational cost, least environmental impact, and high safety. Drillmec fused all these criteria in the HH Series rigs. This series of hydraulic drilling machines are specially designed for safety, efficiency, and speed as well. This is a masterpiece rig ready to deliver optimal results safely.

The HH Series began in 1993 as simple and regular hydraulic rigs for drilling water wells. It was then modified and improved to meet and surpass the demands of oil and gas drilling with the introduction of automation, transportation, pipe handling and self-elevating rig up system. Over the years, this hydraulic rig machine has worked effectively in difficult good conditions and extreme weather conditions around the world. The HH Series is a hydraulic drilling machine that is designed for safety, high performance, reduced emissions, and speed with reduced non-productive time.

DOWNLOAD CATALOG

DOWNLOAD CATALOG

UNIQUE FEATURES

The HH Series are fully automatic rigs with a hydraulic hoist system that contributes to high performance and security. This rig design features various hydraulic equipment that is largely automated to support drilling processes and controlled from the drillers’ cabin. The integration of DEEP (Drillmec’s Embedded Efficiency Platform) brings to board the use of AI data-driven approach to drilling processes. This enables the use of pattern recognition to produce different operational efficiencies while optimizing drilling operations. The driller and crew enjoy safe and simplified drilling operations while on board.

The HH Series is designed with a clear goal of reducing carbon footprint in drilling and production processes. This hydraulic drilling machine features a powerful hydraulic cylinder which is the main hoisting element. It does not have a regular mast structure, drawworks, long wires and travelling equipment as with the conventional rigs. It has a compact design with a reduced height and dropped objects which creates a smaller carbon footprint. Additionally, it has a reduced rig lifecycle GHG emission of roughly 50%, 35% reduction in drilling activities and manufacturing process, and 50% from rig moves which is a big emission reduction when compared to rigs of that size and power.

This hydraulic rig machine is a robust and powerful automated rig offering a high level of safety while delivering outstanding and superlative performance. The advanced automation allows for the central control of most routine drilling operations such as tripping in and out of drill strings with minimal manpower and less time. This ensures proper resource utilization while reducing non-productive time. This hydraulic rig delivers top drive torque range of 13,560 Nm (10,000 lbs/sq.ft.) to 52,230 Nm (38,522 lbs/sq.ft.) and speed of between 120 rpm to 200 rpm. It is available in ratings between 55metric tons (122,000 lbs) to 317 metric tons (700,00 lbs).

The HH Series rigs is designed to have a telescopic mast with a single powerful hydraulic system for a quick and fast erection. All the primary components of the rig are mounted on the wheels making it easier, faster and safer to transport between drill sites. It is also easier and safer to rig up and rig down reducing non-productive time.

DESERT RIGS

Drillmec has built and supplied a considerable number of rigs for various desert regions worldwide. In fact, more than 150 rigs are operating in the MENA region alone. Through the years, Drillmec has extended the desert rigs capacities, models and designed in order to satisfy different needs and serve all the purposes.

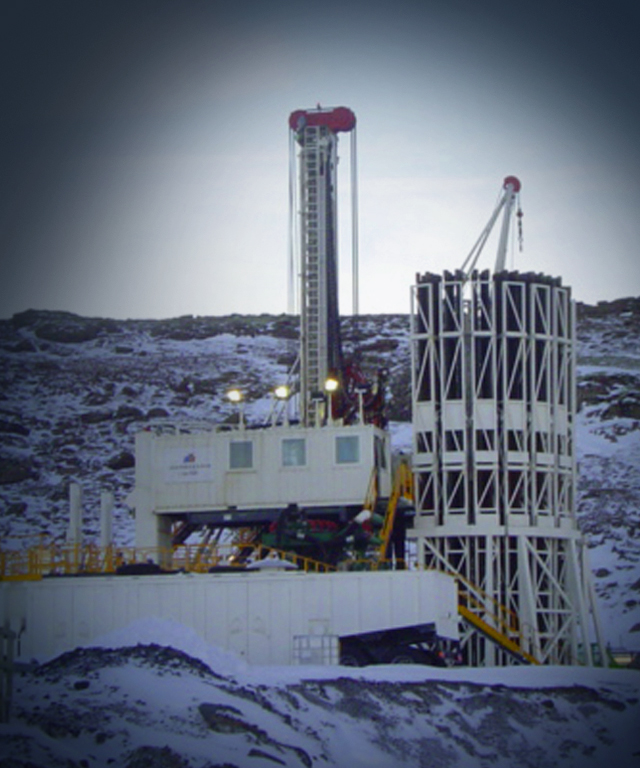

ARCTIC RIGS

Specs

| Input Power | Pull Up | Pull Down | Rated | Top Drive Torque | Top Drive Speed | Rotary Table | Vertical Pipe Rack Capacity (DP 3 1/2") | Vertical Pipe Rack Capacity (DP 5") | Vertical Pipe Rack Capacity (DC) | |

|---|---|---|---|---|---|---|---|---|---|---|

| kW hp | m ton lbs | m ton lbs | m ton lbs | Nm lbs*ft | rpm | mm in | m ft | m ft | m ft | |

| HH 55 | 328 440 | 55 122,000 | 10 22,000 | 55 122,000 | 13,560 10,000 | 120 | 698 27.5 | 1,025 3,360 | 730 2,395 | 110 360 |

| HH 75 | 403 540 | 75 165,000 | 10 22,000 | 75 165,000 | 13,560 10,000 | 120 | 698 27.5 | 1,025 3,360 | 730 2,395 | 110 360 |

| HH 102 | 429 575 | 100 220,000 | 20 44,000 | 100 220,000 | 32,300 23,824 | 120 | 698 27.5 | 2,900 9,500 | 1,800 5,900 | 110 360 |

| HH 150 | 720 965 | 150 330,000 | 20 44,000 | 136 300,000 | 32,300 23,824 | 120 | 698 27.5 | 4,600 15,000 | 3,600 11,800 | 192 630 |

| HH 220 | 1,000 1,542 | 200 440,000 | 20 44,000 | 200 440,000 | 35,840 26,435 | 158 | 698 27.5 | 4,600 15,000 | 3,600 11,800 | 192 630 |

| HH 300 | 1,150 1,542 | 272 600,000 | 30 66,000 | 272 600,000 | 49,080 36,200 | 158 | 952.5 37.5 | 4,624 15,170 | 3,670 12,040 | 192 630 |

| HH 350 | 1,150 1,542 | 317 700,000 | 30 66,000 | 317 700,000 | 52,230 38,522 | 200 | 952.5 37.5 | 4,624 15,170 | 3,670 12,040 | 192 630 |