DRAWWORKS

GDS Series

GDM Series

DRAWWORKS MODELS AND SPECIFICATIONS

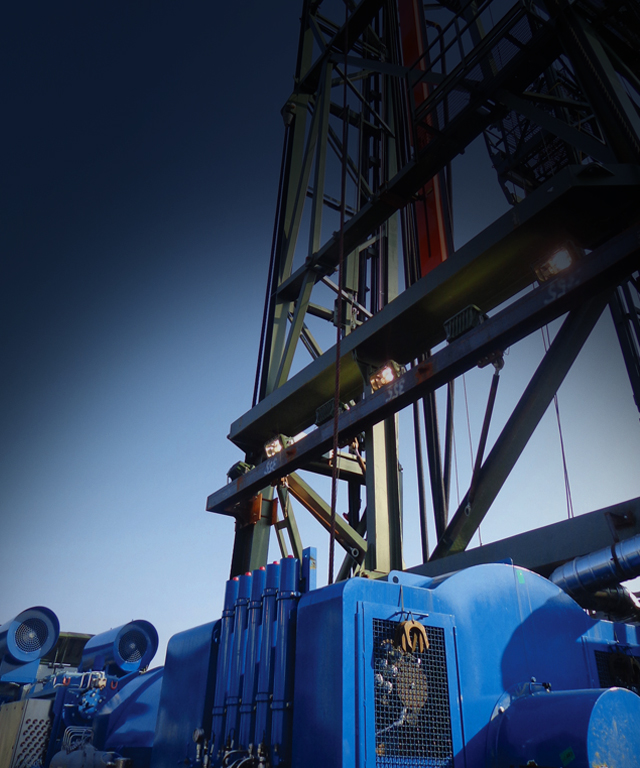

At Drillmec, we produce a wide variety of compact drawworks specially designed to handle difficult challenges. We design our drawworks to handle heavy and tough lifting of drilling strings with the support of the robust gear-driven system that produces between 1,000 to 6,000 hp and that can reach a nominal depth range between 3,500 to 10,000 meters (11,000 ft to 32,000 ft).

GDS SERIES

Horsepower range of 745kw (1000hp) to 2,237kw (3000hp).

Maximum hoisting range of 227 metric tons (500,000 pounds) to 680 metric tons (1,500,000).

Single-speed gear-driven transmission

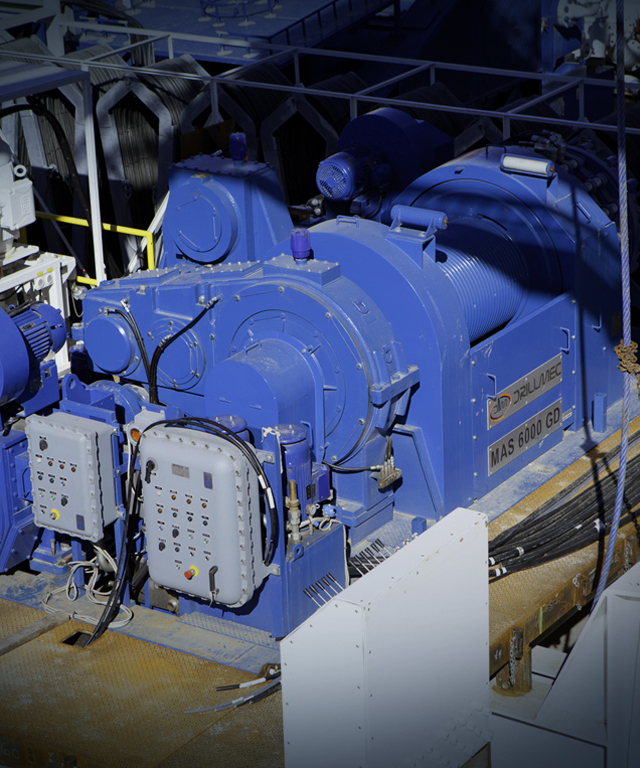

GDM SERIES

Horsepower range between 1,118kw (1,500 hp) to 3,260 kw (6,000 hp).

Maximum hoisting range of 340 metric tons (750,000 pounds) to 1,041 metric tons (2,300,000 pounds).

1 to 4 2-speed gear driven gearbox transmission.

KEY FEATURES OF OUR DRAWWORKS

With a precise optimization of materials and deep stress analysis study, we design compact drawworks with reduced noise and vibration as a result of the inclusion of helical gear in the gearbox transmission.

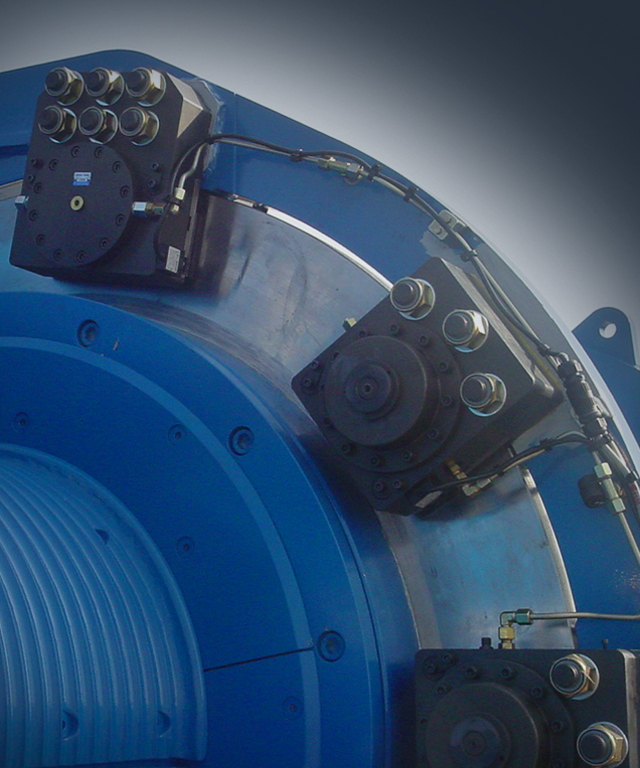

We offer off-the-shelf drawworks that are customizable to meet customers’ specific needs. We have numerous custom solutions that can be included in a drawworks design over the past 10+ years of rolling out excellent fleets of drawworks. The numerous custom solutions include the addition of the braking system with operated spring set disc brake (failsafe) or hydraulic calliper disc brake.

The application of advanced automation technologies in our products is a true reflection of our belief in the continuous pursuit of safety and performance plus the integration of DEEP (Drillmec’s Embedded Efficiency Platform). The addition of HMI allows for the integration of machine learning algorithms that permits the control of repetitive drilling operations through various control systems such as the autodriller, the anti-collision system, and many more in ProRig and ProDriller.

We design our drawworks to integrate a condition monitoring system for proper performance monitoring and maintenance practice. Integration of high-performance monitoring software, part of the ProRig suite, is available to deliver precise conditions and real-time status of the asset. This feature reduces unnecessary downtime and allows for proper planning and management of the equipment.

Specs

| GDS SERIES | Horse Power | Max Hoisting | Transmission | Wireline Size | Motor Assembly |

|---|---|---|---|---|---|

| kW hp | m ton lbs | mm in | kW hp | ||

| GDS 1000 | 746 1,000 | 227 500,000 | Gear driven single speed | 31.8 1 1/4 | 1x858 1x1,150 |

| GDS 1500 | 1,119 1,500 | 340 750,000 | Gear driven single speed | 35 1 3/8 | 2x858 2x1,150 |

| GDS 1600 | 1,193 1,600 | 250 550,000 | Gear driven single speed | 31.8 1 1/4 | 1x1,193 1x1,500 |

| GDS 2000 | 1,491 2,000 | 454 1,000,000 | Gear driven single speed | 38.1 1 1/2 | 2x858 2x1,150 |

| GDS 3000 | 2,237 3,000 | 680 1,500,000 | Gear driven single speed | 44.5 1 3/4 | 2x1,193 2x1,600 |

| GDS 4500 | 3,356 4,500 | 817 1,800,000 | Gear driven single speed | 47.6 1 7/8 | 3x1,193 3x1,600 |

| GDM SERIES | Horse Power | Max Hoisting | Transmission | Wireline Size | Motor Assembly |

|---|---|---|---|---|---|

| kW hp | m ton lbs | mm in | kW hp | ||

| GDM 1500 | 1,119 1,500 | 340 750,000 | 2-speed gear-box | 35 1 3/8 | 2x858 2x1,150 |

| GDM 2000 | 1,491 2,000 | 590 1,300,000 | 2-speed gear-box | 38.1 1 1/2 | 2x858 2x1,150 |

| GDM 3000 | 2,237 3,000 | 771 1,700,000 | 2-speed gear-box | 44.5 1 3/4 | 1x1,193 1x1,600 |

| GDM 4500 | 3,356 4,500 | 907 2,000,000 | 2-speed gear-box | 50.8 2 | 3x1,193 3x1,600 |

| GDM 6000 | 4,474 6,000 | 1,043 2,300,000 | 2-speed gear-box | 54 2 1/8 | 4x1,193 4x1,600 |